Most of us dream about owning our own private home theater complete with state-of-the-art technology capable of recreating the full cinema experience. If you are going that extra step and building one, soundproofing is going to be a key issue.

To stay on the right side of the rest of the household – not to mention the neighbors – you will want to limit the escape of sound to a bare minimum (total soundproofing is impossible in a normal domestic building).

Soundproofing can be a complex area and there is a lot of conflicting information out there. This guide simplifies the science of soundproofing and will help make sure you make the best decision possible when designing and building your exciting new space.

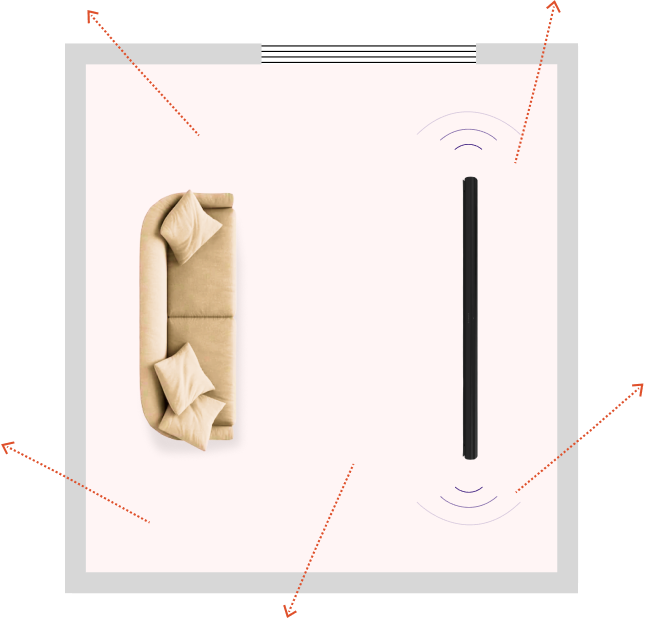

If you want to minimize the amount of sound traveling from your home theater to other rooms and adjoining buildings, it helps to have a basic understanding of how sound works.

Sound travels in waves but unlike the ‘up and down’ waves on a beach (transverse waves), sound waves transfer energy forwards and backwards (longitudinally) by compressing air particles near to the source of the sound. These particles move forward, compressing their neighbors, before springing back (think of it like holding on to one end of a Slinky toy and throwing it forward).

What happens when sound waves enter our ear?

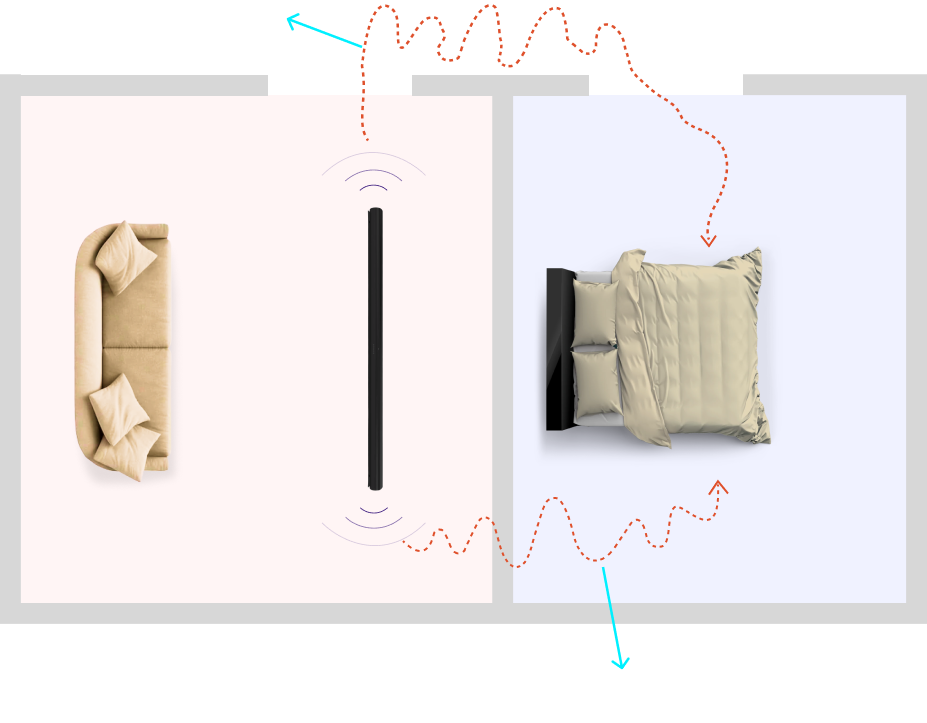

When it comes to soundproofing our homes, it is useful to divide the source of sound waves into airborne sound and structure-borne sound.

Airborne sound reaches our ears directly via the air.

Structure-borne sound, on the other hand, is generated when the connected materials of our homes vibrate, either due to impact (e.g. dropping a dumbbell on the floor) or following contact with airborne sound. In fact, most sounds we hear from another room will have both an airborne and a structure-borne component but let’s keep things simple.

Structure-borne sound travels faster than airborne sound. In terms of frequency, it tends to be in the low range (although you may occasionally hear high-pitched buzzing or ringing from metal surfaces).

Airborne Sound

When thinking about airborne sounds, we need to focus on spaces. In a stud wall, those spaces are between the drywall panels and studs. As sound waves strike the drywall, many of the high and mid-range frequencies are absorbed and end up as heat. The low frequency sound waves are different. They will cause the drywall to vibrate, thus transferring the sound wave through the wall and into the next room.

Structure-borne sound

At the same time, parts of the wall that are connected to or in close contact with the drywall panels will also start to vibrate, propagating structure-borne sound waves through to adjoining rooms. Where the drywall has been rigidly fixed to the studs with screws, there is no barrier to this process.

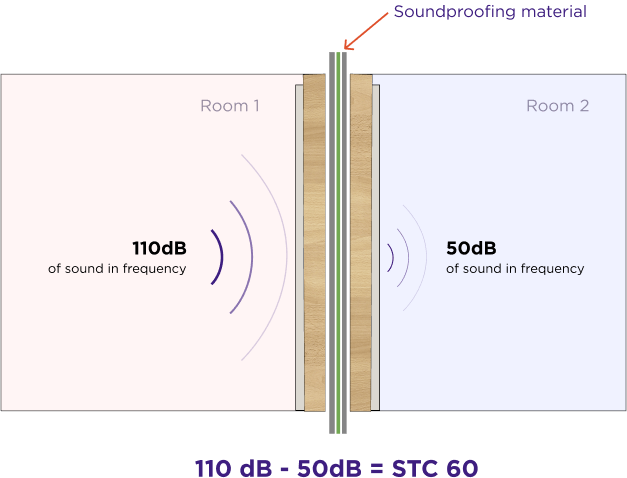

In order to keep sound levels within reasonable limits, the ASTM international standards organization have introduced several standards based on a partition’s Sound Transmission Class (STC).

These standards have been integrated into state building codes and may be specified when you come to get approval for your home theater build. Any material you use in your soundproofing will have an associated STC but you can also improve your home theater’s STC through construction methods such as decoupling (the ‘room within a room’ concept).

Measuring the STC

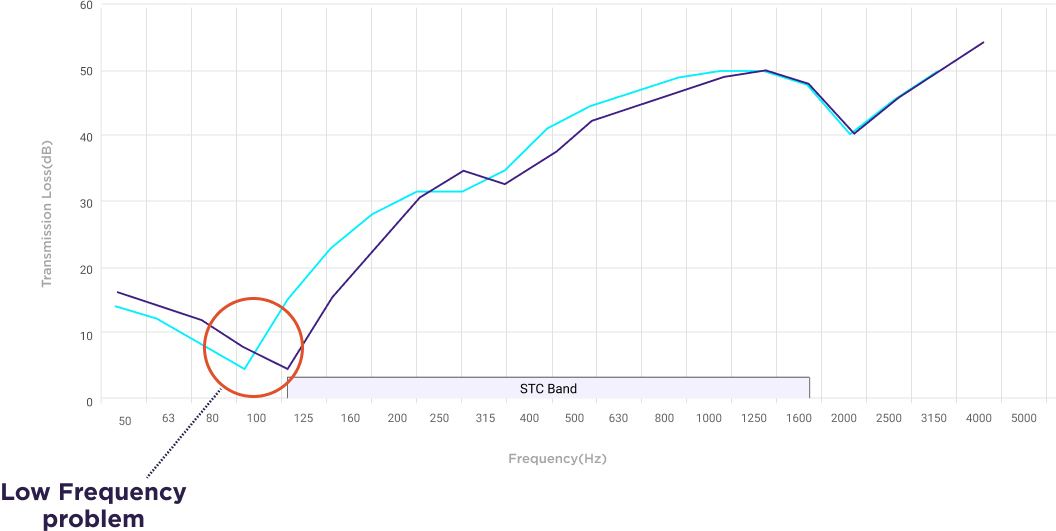

Measuring the STC of a partition can be done under laboratory conditions or in the field. The partition is subjected to sound waves of different frequencies and the loss in sound power (in decibels) is recorded on the other side. The resultant transmission loss (TL) at different frequencies can then be plotted on a graph and an overall STC value given. By studying the graph, you can also see the profile of the partition’s frequency response. For example, you may see a noticeable dip known as the ‘coincidence dip’ which shows at which frequency the partition will resonate.

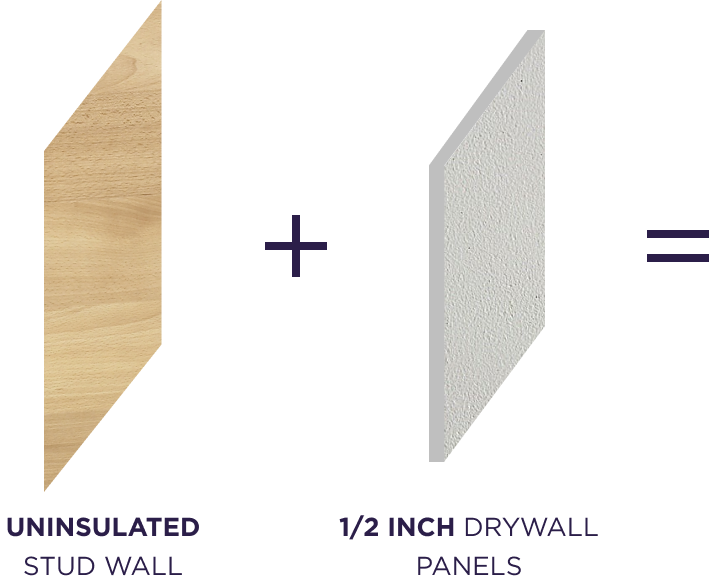

STC 33

This provides poor soundproofing and you would be able to hear and sometimes even understand raised voices on the other side.

This type of wall does not meet International Building Code (IBC) standards for new build properties as this stipulates a minimum rating of STC 50.

Adding a second drywall panel with a dampening compound between them will push the STC up to around 52, meeting most building code regulations. Voices will no longer be heard and the sound from your loudspeakers will be faint. You may still find that your subwoofer is intrusive at loud volumes though.

The low frequency problem

The STC system was formed around standard household activity including walking around, cooking, washing, talking, etc.

Most of these activities occur within mid to high-frequency bands and, as a result, low frequencies were omitted from the STC tests. Low-frequency noise is emitted from a range of sources from industrial machinery and vehicles to thunderclaps and, of course, bass frequencies from musical instruments and subwoofers.

Unfortunately, it is within these low frequency ranges that many materials and partitions fail significantly. Therefore, despite providing minimal resistance to low frequency sounds, materials often pass the ASTM threshold.

Why?

Why are low frequency sound waves so difficult to control?

Whereas it takes a lot of energy to make a surface vibrate at a high frequency, even low energy sound waves are powerful enough to make most substances vibrate enough to transmit low frequency sound.

The solution seems simple: install a completely stiff material that doesn’t move at all. Sadly, such a material exists only in the realm of science fiction so we are restricted to limiting movement as much as possible and/or absorbing the energy from sound waves internally via pores and air channels. We can also use particulate fillers such as sand to transform some of the sound energy into heat via friction.

If you’re looking to protect fellow inhabitants from your subwoofer, the easiest way is to add as much mass as possible to your surfaces and preferably use smart composite materials that perform well against low frequency sounds.

2x

Doubling of Mass

6dB

reduce sound by 6dB

Every doubling of mass reduces sound power output by 6 decibels but even then it is notoriously difficult to block low frequencies completely. That’s why many home theater builders turn to construction techniques such as decoupling to better contain sound.

Clearly, the type of materials you use in constructing your home theater will significantly affect how much sound energy is transmitted into adjoining rooms and their frequencies. Materials have different levels of porosity (inner space) and resonance which determine whether sound waves are absorbed (dampened), reflected or even amplified.

Each material has its own Sound Reduction Index but since this is only an average taken from tests performed at the 100Hz to 3kHz range, its performance at the lower end of the frequency spectrum is not included.

Sound Reduction Index Test Range

Regardless of the material involved, adding mass to any surface will reduce vibrations so if in any doubt, go for the heavier material.

Starting with the walls, most home theaters will include a variation on the classic stud wall design with two by four or two by six timber used to construct an inner wall. After that there is an element of choice about the materials you choose for insulation, paneling and wall coverings

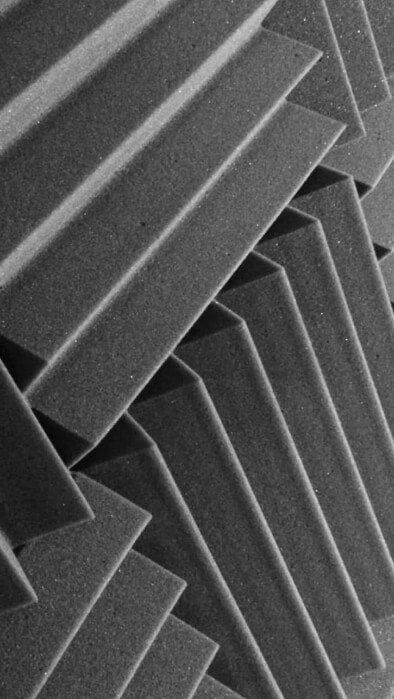

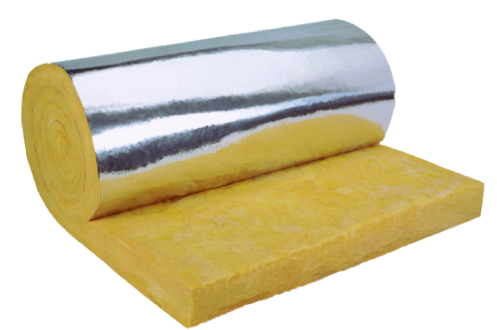

Insulation

Insulation plays a fairly minor role in soundproofing but fibrous materials are better than foams.

Loosely packed fibers

Loosely packed fibers can absorb some frequencies, notably in the high and mid-range frequencies

Foam insulation

Foam insulation, despite its superior insulating properties, hardly impedes sound at all.

fiberglass insulation

Home theater designers should opt for a standard fiberglass insulation over foam.

Mineral wool

Mineral wool is just as effective but costs a lot more for no extra benefit.

open cell foams

If you do go for foam, open cell foams are very porous and do a better job of absorbing medium to high frequency waves, converting them into heat through internal friction. These materials are better for soundproofing insulation than closed cell foams.

Drywall

There are good reasons why drywall such as Sheetrock™ (also called plasterboard, wallboard or gypsum board) is popular as a paneling material. It is fairly inexpensive, readily available and easy to work with. Adding an extra layer of drywall to your stud wall will help to stop high and mid-range frequencies but will have only a minor effect on low frequencies unless you use a dampening compound.

Soundboard

Sound-deadening fiberboard (e.g. SoundChoice™ or Homasote™) can be useful as a spacing layer in floors but its low mass makes it of minimal value as a soundproofing material for your walls.

MLV

Mass-loaded vinyl such as Acoustiblok™ and SheetBlok™ can be useful for wrapping ducts, pipes, and exposed columns but as a dampening layer adds little in the way of soundproofing, especially considering its cost.

Dampening compound

If you are introducing mass by adding an extra layer of drywall to your walls or ceilings, a dampening compound such as Green Glue™ or Decibel Drop™ is highly recommended. These are fairly inexpensive viscoelastic adhesives that combine the energy absorbent properties of elastic with the dampening properties of a thick fluid; they can even be quite effective against low-frequency sound.

If you are adding extra drywall to your ceiling, using a hydraulic drywall jack will make life far easier. Dampening compounds can also be used when bonding underlay to subfloors.

Damped drywall

Damped drywall (sometimes called pre-damped drywall or damped gypsum) is the commercially available version of what has already been described – sandwiching a layer of dampening material within two sheets of drywall.

Different brands come in at different price points but will usually cost more than going down the DIY route.

Single Sheet

$8-$12

Green Glue

75c per square foot

SoundBreak XP

$50

QuietRock™ ES, currently at $80 to $110 a sheet is the next most affordable option but for a THX-approved panel with proven performance at low frequency ranges you are looking at a minimum of $350 per panel (e.g. QuietRock 545).

Acoustic sealant/caulk

However you intend to soundproof your home theater it is imperative that you remember your acoustic sealant. All gaps between and around panels, fittings and fixtures need to be sealed to prevent the transmission of airborne sound waves.

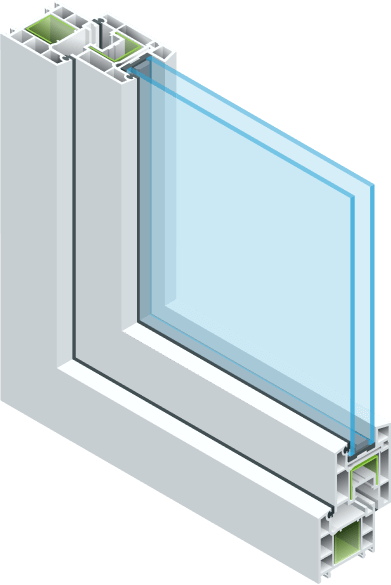

Pre-built fixtures

Rather than soundproofing every aspect of your home theater yourself, you may find that there are modular units that are already soundproofed and can be built into your design. Pre-built soundproof doors and windows are readily available and will save you plenty of time if you don’t mind paying a little extra.

Novel materials

Achieving a balance between all the factors needed to effectively soundproof a room is tricky. Materials need to provide an effective barrier against a wide range of frequencies while also being lightweight, environmentally friendly, cost-efficient and resistant to physical, chemical and biological damage. It is worth staying updated on industry news as you may come across a brand new product that ticks all the boxes.

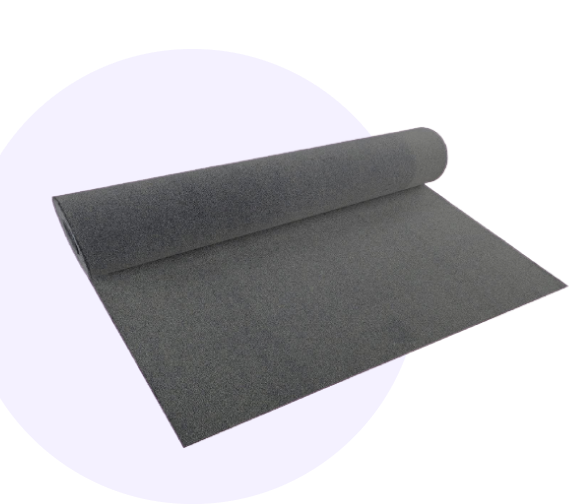

Floor underlayment

Floors are less important for soundproofing if you are building your home theater in the basement but what if there are rooms below and you are unable to alter the ceiling?

In this situation, a soundproof underlayment between your floor covering and your subfloor will be vital. There are plenty of materials you could use and each have their benefits and disadvantages. Shredded or foamed rubber is quite effective but to meet building codes this will usually need to be at least 6mm thick. This will make it heavy, expensive and hard to install.

Natural fibers or cork can work but only if the floor isn’t prone to damp as mold is a risk. On the other hand, bituminous membranes are easy to install, mold resistant and durable but it turns out that they are not very good at soundproofing. Whatever underlayment you choose for your floor, you will have to make compromises.

Every now and then, acoustic and materials specialists come up with novel materials that they claim solve the soundproofing issue. If you are planning to soundproof a home theater, keep an ear on the industry news for any new developments.

If you realistically want to push your STC level above 60 while absorbing the worst of your bass frequencies, you will almost certainly need to look into decoupling techniques.

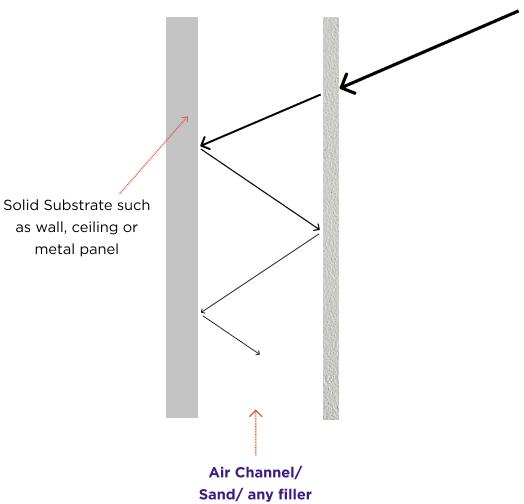

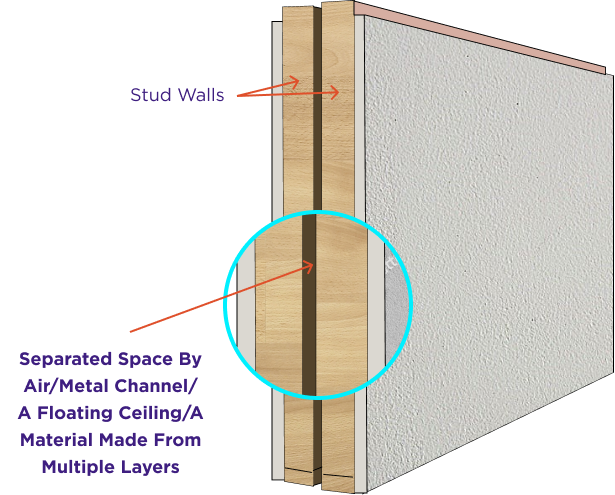

Decoupling covers any system whereby two adjoining surfaces are separated from one another.

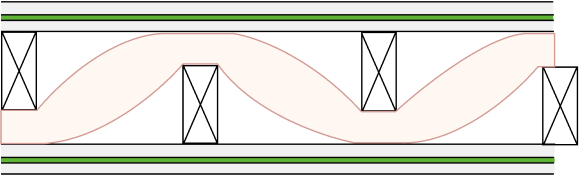

This might include a ‘double wall’ system where two stud walls are separated from one another by metal channels; a floating ceiling or simply a material made from multiple layers and where the top and bottom layers are separated from one another by one or more barrier layers.

How?

How does decoupling benefit soundproofing?

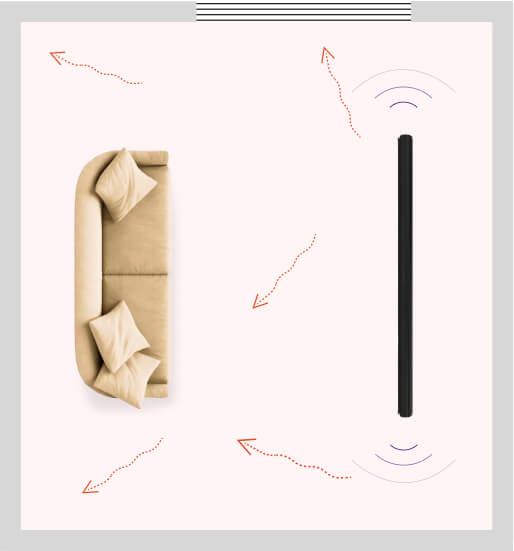

Looking back to how sound waves transmit energy through a structure, you can see how decoupling would mainly affect structure-borne sound, those vibrational waves transmitted through the physical structures of the building. This suggests that decoupling could solve some of the problems with low frequency sound transmission.

However, things are not quite so simple, especially with spatially separated structures such as double walls and floating ceilings. Since low frequency airborne sound waves are poorly attenuated by most wall and floor materials, these will pass into the spaces created by the decoupling process.

If Separation space is not large

If that space is not large enough, it can sometimes cause the materials to resonate. If you’re not careful, you could end up effectively amplifying airborne low frequency sounds by creating a resonance chamber.

If Separation space is too large

On the other hand, if you make the space too large, you eat into your home theater space.

This example should serve to illustrate that even decoupling on its own is not the silver bullet of soundproofing. You need to combine adding mass, choosing smart materials and decoupling to finally achieve a fully soundproofed room.

Hardware for decoupling

There are various types of hardware which can help you to make your decoupling project a success.

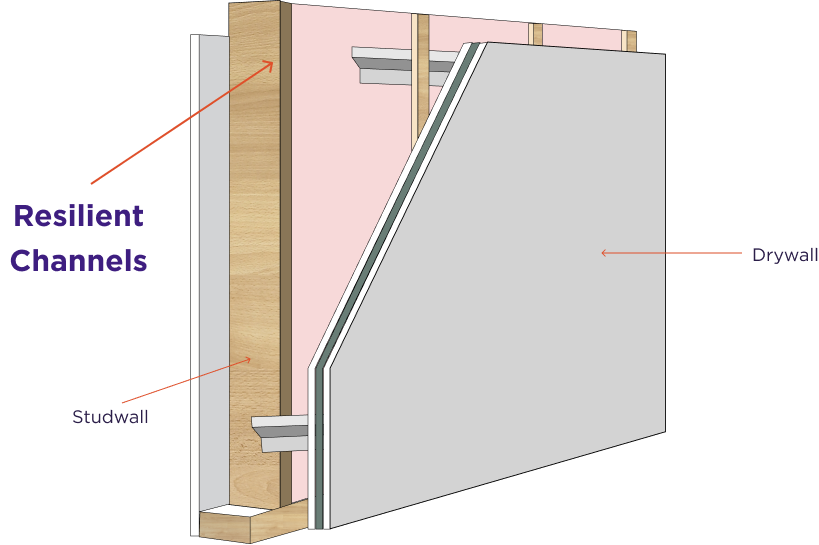

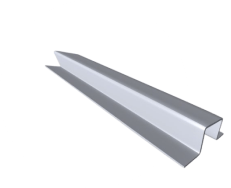

resilient channels

Many people with an interest in soundproofing will have heard of resilient channels. These are L-shaped metal strips which are laid across the studs or joists of the wall or ceiling you are soundproofing to minimize structure-borne sound passing from the drywall to the wood. The drywall is attached to the resilient channels with small screws to avoid them contacting the stud beneath and transmitting sound.

Resilient channels (RCs) are relatively inexpensive so are ideal for the budget-conscious home theater designer. However, there is a lot of variation in quality and they must be installed correctly or their soundproofing quality will be diminished. Resilient channels are designed with a flange at the bottom which is screwed to the wood leaving the top loose.

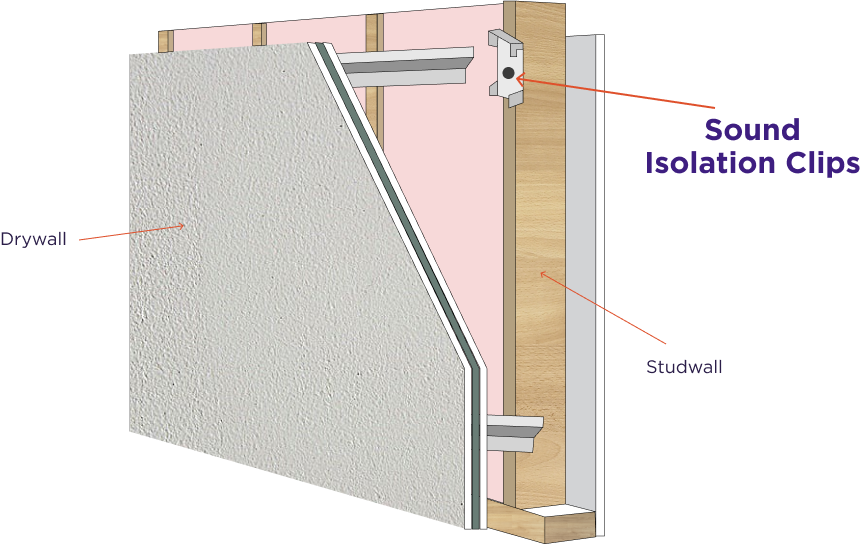

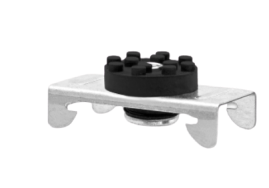

Sound isolation clips

Sound isolation clips are rubberized metal connectors which are attached to the wall studs and connect with hat or furring channels, U-shaped strips of metal (steel or aluminum).

As with resilient channels, they help to isolate the attached drywall from the studs while the rubber in the clips does a good job of minimizing structure-borne sound transmission. Sound isolation clips and hat channels are a bit easier to install than RCs, provide better soundproofing and are less prone to sagging. Their only downside is that they can be quite expensive.

Decoupling materials

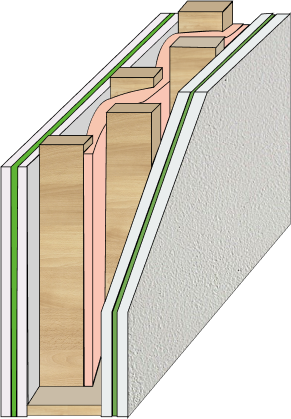

The concept of decoupling can also be used in soundproofing materials.

Decoupling materials will include a minimum of three layers with the top layer/s separated from the bottom layer/s by one or more middle layers.

A decoupling underlayment can be put between tiles and a subfloor for soundproofing purposes.

Top layer

The top layer might be made from fabric, foam, rubber or another flexible material.

Middle layer

The middle layer might be made from a rigid material like aluminum foil. The middle layer is designed to stop as much of the sound coming through to the bottom layer/s as possible

Bottom layer

The bottom layer/s might be made from a viscoelastic damping compound to absorb any remaining sound waves.

As an alternative to decoupling, some acoustic specialists have come up with soundproofing systems based on specially engineered interlocking panels.

In a nutshell, there are three areas of soundproofing you need to address when designing your new home theater: walls (including doors and windows), ceiling and flooring.

Designing your interior

soundproof walls

As detailed already, the best design for a soundproof home theater wall is a decoupled double stud wall. The main drawback of this design is the room space you will lose. An alternative design is a staggered stud wall that uses a 2×6 base plate with 2×4 studs set in an alternating pattern. This reduces the space required while increasing the air cavity over a single stud wall. However, the double-wall design is far more effective if you can do without the space.

Top Section View

(Wall Staggered Stud)

If you do opt for double walls, paying a little extra for sound isolation clips and hat channels will probably edge resilient channels in terms of soundproofing and ease of installation.

Standard fiberglass insulation is a better choice than foam and, depending on your budget, either pre-damped drywall or a double layer of drywall with Green Glue in between will serve you well as paneling.

Standard fiberglass insulation

Rather than spending time soundproofing doors and windows, consider buying pre-made units.

Where you need to cut the drywall, make sure you apply acoustic sealant and the same applies to any seams.

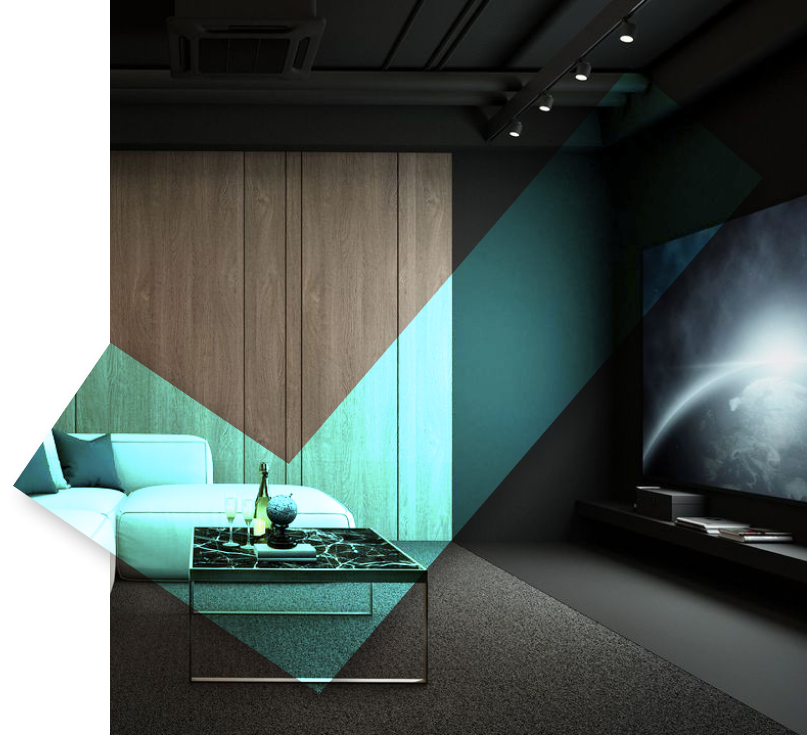

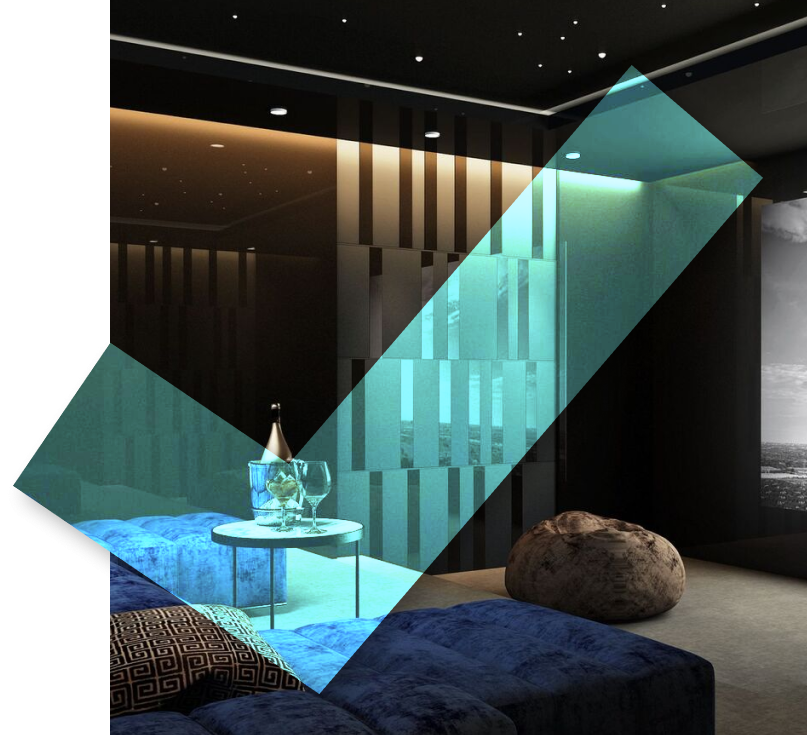

Choosing your ceiling

Dropped ceilings are popular with home theater owners because they not only provide plenty of space for running cables and housing lights, in-ceiling speakers, and mounts for projectors but they also improve soundproofing.

As with stud walls, you can affix your pre-damped drywall (or DIY drywall/Green Glue sandwich) to hat channels clipped into sound isolation clips. Renting a hydraulic drywall jack is highly recommended for this process.

Flooring options

A multi-layered underlayment between your chosen floor surface and subfloor can make a big difference to soundproofing although noise won’t be much of an issue unless there are rooms beneath your home theater.

Underlayment with elastoviscous properties will help dampen sound but if you can find a decoupled product with a barrier layer, this will be even better.

Soundproofing

Reducing the sound waves traveling outside of your home theater

The easiest way to separate out the concepts is to think of soundproofing as being about reducing the sound waves traveling outside of your home theater and into other areas of the home (and adjoining homes).

Acoustic control

Managing the sound waves inside your home theater

Acoustic control is about managing the sound waves inside your home theater to maximize the enjoyment of your movie experience.

Confusing the concepts can cause problems!

For example, installing wall-to-wall acoustic panels may stop those annoying reverberations that drown out character dialog but will do little to protect your fellow housemates from noise.

On the other hand, if you install a soundproofing material that reflects rather than absorbs low-frequency sound waves, your neighbors will thank you but you could ruin your movie experience unless you also take steps to control the acoustics within the room.

Fortunately, there are many ways to fine-tune your room acoustics.

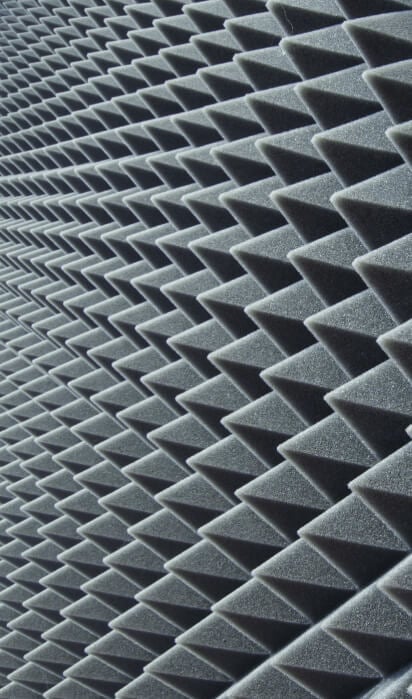

Acoustic panels

Acoustic panels come in all shapes, sizes, and colors. They help to reduce the resonance of hard surfaces, improving the quality of your audio. Panels can be attached to the wall or, for more control over their placement, you can buy free-standing versions.

Sound curtains

Specialized sound curtains include a heavy layer of mass-loaded vinyl. These can help with both your soundproofing and room acoustics.

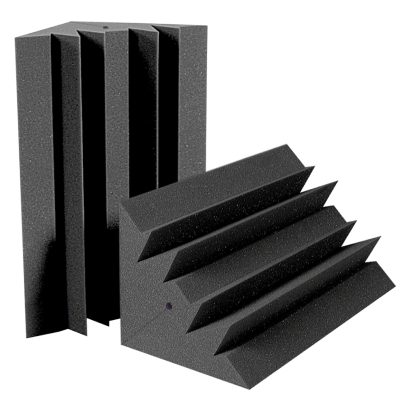

Bass traps

As the name suggests, bass traps help to dampen your low frequencies producing a flatter bass sound. As with acoustic panels, bass traps are available in many different shapes, sizes, and colors.

As the name suggests, bass traps help to dampen your low frequencies producing a flatter bass sound. As with acoustic panels, bass traps are available in many different shapes, sizes, and colors.

Carpet tiles

Carpet tiles are popular in home theaters, especially where the ceiling has a hard surface and you need to balance it. Not only do carpet tiles help with acoustic control by absorbing sound waves, but they also help to evoke that luxurious movie theater ambiance.

Carpet tiles are preferable to fitted carpet in most cases, especially if your home theater is in the basement. Despite waterproofing measures, basements are the area at most risk of flooding and dampness. If the worst happens, it is much easier to switch out one or two tiles than to have an entire carpet replaced.

Home theater seating

Did you know that your choice of home theater seating can also impact on acoustics? If your room contains a lot of hard surfaces and is prone to distracting reverb, purchasing movie theater seats with upholstered plywood bases can help absorb some of those errant frequencies, especially if you are installing multiple seats and rows.

Room equalization

Room equalization involves adjusting the frequency output of your speakers to match the acoustic properties of your room. Many AVRs include ‘room control’ apps with some giving you complete parametric control over your audio output. Older models may use simple graphic equalizers for adjusting broad frequency bass, mid and treble outputs.

Room equalization involves adjusting the frequency output of your speakers to match the acoustic properties of your room. Many AVRs include ‘room control’ apps with some giving you complete parametric control over your audio output. Older models may use simple graphic equalizers for adjusting broad frequency bass, mid and treble outputs.

By spending ample time soundproofing your home theater and fine-tuning your acoustics, you will be able to deliver a fantastic home movie theater experience while keeping the neighbors on side.

How does sound travel through the air?

Sound is transmitted as waves through the air. These waves are generated by vibrating objects, causing a sequence of compressions and rarefactions in the surrounding medium, which in this case is air. Our ears perceive these compressions and rarefactions, and our minds interpret them as sound. It is important to note that sound necessitates a medium for propagation and cannot travel in a vacuum.

How is sound transmitted through walls?

Sound can be transmitted through walls via structure-borne noise. When sound energy encounters a wall, it induces vibrations in the wall material. These vibrations then propagate through the wall, ultimately radiating on the other side as sound. The quantity and nature of the sound transmitted can be influenced by the wall’s material type and density. Generally, heavier and denser materials tend to diminish the amount of sound transmitted.

What is the best insulation to use for soundproofing?

When it comes to soundproofing, choosing the right insulation is crucial. While the specific needs may vary, mineral wool, also known as rock wool or slag wool, is widely recognized as an excellent soundproofing material. Its density and non-directional fiber orientation are key factors that effectively trap and dissipate sound waves. Moreover, mineral wool is fire-resistant, easy to install, and equally suitable for residential and commercial soundproofing applications. Nevertheless, it’s always advisable to seek professional advice to determine the most suitable insulation for your specific situation.

What is sound decouping?

Sound decoupling is a technique used in soundproofing to physically separate or disconnect a structure’s components to reduce the transmission of sound waves. This is done by adding a resilient material between the elements of the structure, often using specialized clips or brackets. The idea is to create a “gap” or “soft spot” in the construction that breaks the path of the sound wave, preventing it from moving from one side to the other. This method is particularly effective in reducing the transmission of low-frequency noise, such as bass sounds.

How do you soundproof a ceiling?

Soundproofing a ceiling requires several key steps. Firstly, you’ll need to install resilient clips and furring channels to separate the ceiling, effectively interrupting the transmission of sound. Afterward, fill the space between the ceiling joists with a dense, sound-absorbing material like mineral wool insulation. Then, add two layers of drywall, incorporating a damping compound in between to further obstruct sound. Be sure to seal any potential gaps or air leaks with acoustical sealant. Keep in mind that each situation is unique, so you may need to modify these steps to suit your specific requirements.

What is acoustic control?

Acoustic control encompasses the management and manipulation of a space’s acoustic characteristics. Its purpose is to enhance sound quality and mitigate noise propagation. This practice finds applications in concert halls, recording studios, theaters, and even residential homes. Achieving acoustic control involves a combination of measures like soundproofing, using sound-absorbing materials, and optimizing the room’s shape and materials. By implementing these strategies, the desired acoustic environment can be achieved, providing an immersive and enjoyable auditory experience.

What is the purpose of bass traps?

Bass traps are ingenious devices utilized to enhance the acoustic quality of a room by minimizing the impact of low-frequency sounds. Their purpose is to absorb bass and other low-frequency sound waves, which pose a particular challenge due to their length and energy. These traps find great utility in recording studios, home theaters, and other spaces where sound clarity is of paramount importance. By mitigating the resonance of low-frequency sounds, bass traps effectively eliminate issues such as ‘bass build-up’ and ‘flutter echoes’, thereby contributing to a more harmonious and pristine sound environment

What is a good STC rating?

The Sound Transmission Class (STC) is a numerical indicator of the effectiveness of a barrier, such as a wall, window, or door, in reducing the transmission of airborne sound. An STC rating serves as a valuable tool in the design and selection of soundproofing materials. Generally, a higher STC rating signifies superior sound insulation. For instance, a rating of 25 implies that conversations can be easily understood through the wall, while a rating of 50 or higher indicates excellent soundproofing, where loud sounds are attenuated to a mere murmur. In most residential and commercial applications, a good STC rating falls within the range of 35 to 55. However, environments requiring heightened sensitivity to sound, such as recording studios or home theaters, may necessitate materials with an STC rating of 60 or higher.

How do you get rid of low frequency sound?

Elim low-frequency sounds can pose a challenge due to their pervasive nature. However, there are several effective strategies that can be employed to attenuate these sounds. One such method involves the use of bass traps, which are specifically designed to absorb low-frequency sounds. Placing these traps in the corners of your room, where bass tends to accumulate, can provide significant relief. Moreover, implementing soundproofing measures such as installing dense insulation, using soundproofing drywall, and decoupling structures can help reduce the transmission of these sounds. Additionally, for appliances and equipment that generate low-frequency noise, it may be worth considering the use of anti-vibration pads or isolation platforms. It is important to remember that each situation is unique, and the most effective approach will depend on the specific sources and characteristics of the unwanted sound.

What is the most effective soundproofing material

The effectiveness of a soundproofing material depends heavily on the specific requirements of the situation. However, Mass Loaded Vinyl (MLV) is often praised as one of the most efficient soundproofing materials due to its high density and flexibility. MLV can be applied to walls, ceilings, and floors to minimize airborne noise, particularly low-frequency sounds. Another notable option is Acoustic Foam, known for its lightweight nature, easy installation, and excellent absorption of high-frequency noises. Additionally, Green Glue Noiseproofing Compound proves highly effective when applied between layers of drywall, reducing both airborne and impact noise. It is important to note that the effectiveness of soundproofing techniques, such as decoupling and damping, can also be enhanced through proper application.

How do you decouple a wall?

Decoupling a wall for soundproofing involves creating a physical gap between the two sides of a wall to prevent sound transmission through solid materials. Here’s a basic step-by-step guide:

- Remove the existing drywall or plaster from one side of the wall to expose the studs.

- Install resilient channels across the studs horizontally, starting from the bottom and working your way up. These channels serve as the decoupling element and should be spaced around 24 inches apart.

- Attach new drywall onto the resilient channels. Do not allow screws to penetrate into the studs, ensuring the drywall is only attached to the channels.

- Seal all edges and seams with acoustical sealant to avoid any sound leaks.

Remember, successful decoupling will interrupt the path of the sound, preventing it from vibrating through the structural elements of the building. However, this method is more effective when combined with other soundproofing techniques, such as adding mass and absorption.

How do you soundproof a floor?

Soundproofing a floor involves several steps aimed at reducing both airborne and impact noise. Here’s a basic guide:

- Start by evaluating the type of noise you’re dealing with. If you’re looking to block sound from an upstairs room, you’ll likely want to focus on impact noise, while airborne noise should be your focus for sounds coming from below.

- Install a layer of mass-loaded vinyl (MLV) on your subfloor. This dense material will help block airborne noise and add mass to your floor.

- Add a layer of acoustic underlayment. This will help to reduce impact noise and further enhance the sound-blocking capabilities of the MLV.

- Install the new flooring over the underlayment. This could be anything from hardwood to carpet, depending on your preference.

- For added soundproofing, consider using acoustic sealant around the edges of the room to seal any gaps.

Remember, the success of your soundproofing efforts will depend largely on the type of noise you’re dealing with, the construction of your floor, and the soundproofing materials you choose to use.

Where do you put acoustic panels?

Acoustic panels are most effective when strategically placed at the points where sound reflects. These points are typically the areas where sound bounces off after being emitted from the source. In a room, the initial reflection points are usually the walls directly to the left and right of the audio source. For optimal results, mount the acoustic panels on these walls at ear level. You can also consider installing additional panels on the rear wall, ceiling, and even the floor to further reduce echo and enhance sound quality. However, it’s important to note that the placement of acoustic panels may vary depending on the unique acoustics and layout of your room. Therefore, it is recommended to experiment with different placements or seek advice from an acoustics specialist.

How can theater seating impact acoustics?

The arrangement of seats in a theater can have a significant impact on the acoustics of the space. The material of the seats themselves is a crucial factor that can either absorb or reflect sound, directly affecting the overall sound quality. For instance, upholstered seats tend to absorb sound, reducing echo and enhancing clarity. Moreover, the positioning and layout of seats also play a pivotal role. The spacing between rows and seats can alter the path of sound waves, influencing how sound travels and is perceived throughout the theater. Additionally, when the theater is fully occupied, the human body acts as a substantial absorber of sound, further modifying the acoustics. Therefore, when designing and arranging theater seating, it is vital to consider acoustics as a key factor to ensure optimal sound quality for all attendees.