High Resilience foam

VS

Conventional foam

Your choice of foam can make a big difference to your life.

Foam cushions are a primary feature of most upholstery furniture with the quality of foam defining its comfort levels. The type of foam inside your furniture can have a huge impact on your overall health, from posture and circulation to digestion and energy levels. In other words, your choice of foam can make a big difference to your life.

High resilience foam and conventional foam are two of the most common types you’ll find in your furniture.

Each kind of foam has unique properties that affect how your furniture feels when you sit on it. This article will discuss their differences and which one to choose to receive the greatest benefits from your furniture.

What is

High Resilience Foam?

If you’re beginning to really consider the properties of a sofa before you make a purchase, it’s definitely worth looking at high resilience (HR) foam.

The furniture-aficionados among you may have already encountered this material, as it’s becoming increasingly popular with manufacturers for its range of beneficial properties.

High resilience foam is a type of polyurethane foam used as cushioning in a range of furniture and commercial products such as sofas, vehicle interiors, and bedding.

HR foam is characterized by its ability to bounce back up after pressing it compared to memory foam which sinks and rises back very slowly.

The springy quality of HR foam stems from its unique open cell structure that provides durability, elasticity, and enhanced support, making it an ideal component for furniture.

High Resistance Foam Firmness Levels

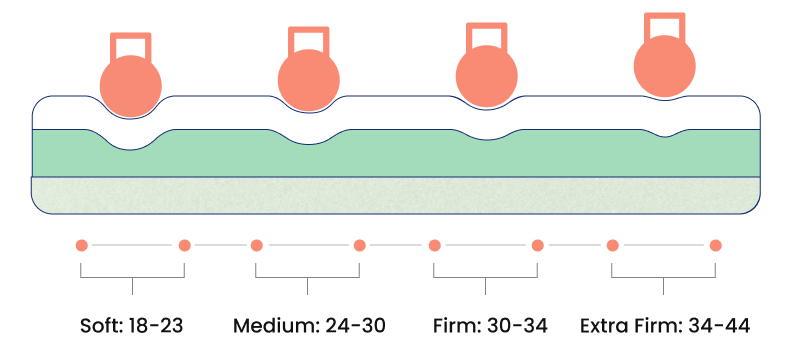

Foam firmness refers to how much the foam compresses after pressing it. The firmer the foam, the less it compresses. Foam firmness is also known as indentation load deflection (ILD) or Indentation Force Deflection (IFD) and is a measure of softness that ranges between 10 and 60 or more.

The common descriptions of foam firmness are as follows:

You can use these descriptions to determine how firm or soft your furniture will be. Foam firmness, alongside foam density are indicators of the strength and quality of your sofa or mattress. You can find HR foam in a range of firmness levels to suit your needs and specific uses.

High Resistance Foam Density

Foam density refers to the heaviness of the foam and is a measurement you can use to calculate the longevity of your furniture.

The denser the foam, the greater its elasticity and resilience. Foam density measures in pounds per cubic foot, calculating the number of pounds that each cubic foot can withstand.

HR foam can have a density of around 3 lbs to 6 lbs, meaning that it is extremely durable and should last up to 12 years of daily use. Foam density and foam firmness are two different measurements, and a dense foam does not necessarily equate to a firm foam.

Foam density is certainly a factor you should consider when purchasing upholstery furniture.

If you plan on getting good daily use from your sofa or mattress, a high-density foam can ensure it maintains its quality and resilience for a long time. However, if you purchase an accent chair for a guest room that is unlikely to receive much traffic, you can afford to save money with a lower-density foam.

Is High Resilience Foam

The Same As High Density Foam?

High resilience foam and high density (HD) foam are not the same material, despite commonly being confused for one another.

High resilience foam is incredibly supportive, flexible and highly durable, making it ideal for heavy-duty furniture. High density foam shares similar properties to HR foam, but is not widely used as the exclusive foam in furniture, owing to its firmness.

The load distribution properties of high resilience foam also make it a popular choice for furniture, since it is far more comfortable to sit or lie down on.

If you enjoy a subtle bounce in your furniture, you may gravitate more toward high resilience foam. If you’re a fan of more solid structures, however, high density upholstery foam is the one for you.

HR foam offers far better support and durability than conventional foam,

but the same is not always true for HD foam types. While HR foam can quickly bounce back to its original form, other types of foam are less springy, instead offering worse support or more rigidness.

Versatility of High Density Foam

As the name suggests, high density foam is extremely heavy and firm. As such, it’s not commonly used as the exclusive material in mattresses or sofas, but rather as a supporting layer on the bottom.

HD foam is typically used as a foundation because of its incredible rigidity and support capabilities. Since it lacks the comfort of other foam types, however, it’s only used as a bottom layer.

The term “high density foam” refers to the foam’s mass per unit of volume. High density foams, therefore, weigh a lot more than conventional foams and some high resilience foams.

Differentiating Between High Resilience Foam And High Density Foam

Despite their differences, HR and HD foams share many similarities. In fact, many HR foams can have high densities, and many HD foams are extremely resilient. This makes it hard to determine what exactly is a HR foam and what is a HD foam, especially since hybrid materials also exist.

That said, this is not always the case. Not all high resilience foams have a high density, since there are many lightweight foams that are incredibly durable. Similarly, a high density does not equate to a high resilience.

Some HD foams may actually be less resilient

In fact, some HD foams may actually be less resilient than lower density foams, depending on how they are manufactured and what materials are used in their construction.

In light of these subtle distinctions, HR and HD foam provide different functions when used in furniture. It’s important to ascertain their differences when choosing between the two during the construction phase, because each offers unique properties that are better suited to a specific function.

HR foam is better for comfort, while HD foam is more suited to sturdiness.

What is

Conventional Foam?

Conventional foam is a term used to describe a range of different materials that are commonplace in everyday life. Chances are, you’ll have touched, squashed, or sat on a piece of conventional foam during your lifetime, since these materials are used in a variety of applications.

Where would you find conventional foam, then?

Well, almost everywhere. Since conventional foam can be produced comparatively cheaply and the material itself is incredibly versatile, it can be used in a wide range of furniture, packaging, and insulative applications.

From cushions on your average sofa and car seats to safety packaging in fragile parcels, conventional foam has a number of different uses.

It’s most commonly made from one of three different materials:

C3H8N2O

Polyurethane

(C2H4)n

Polyethylene

(C8H8)n

Polystyrene

We think it’s fair to say that the average person has probably only heard of one of these. Polystyrene is not uncommon in the English language, especially when referring to packaging. The other two are normally never said out loud, unless you’re a scientist or manufacturer.

Below, you’ll find some more details on the three types of conventional foam:

Polystyrene:

This type of conventional foam is most commonly used in one of two applications: packaging and insulation. Since they contain around 98% air, polystyrene foams are incredible at providing security for fragile objects without breaking them.

This lightweight property also makes polystyrene a great insulator, so it’s used to keep rooms nice and toasty.

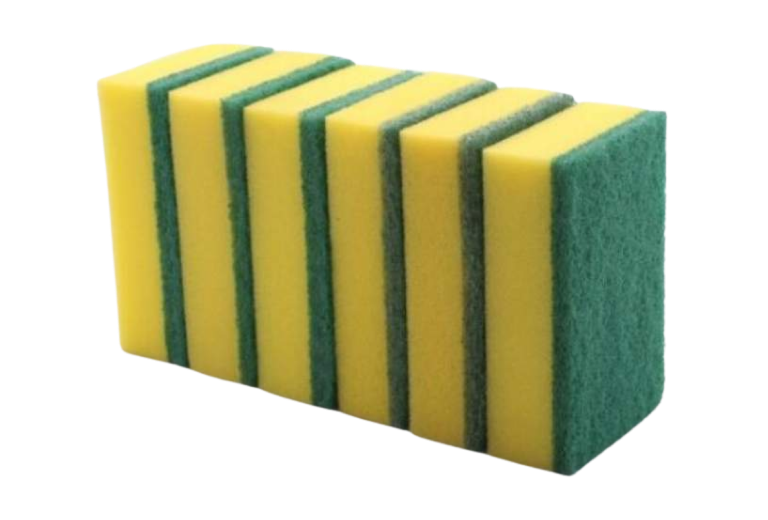

Polyurethane:

A common type of foam used in a number of everyday applications, like kitchen sponges, scourers, and soundproofing. It also makes a great insulator and is typically used in house construction as insulation. High density polyurethane foam is particularly firm

Polyethylene:

Not the strongest of foams, polyethylene is still a great insulator. It exerts low friction and has a high impact strength, making it useful in certain situations. Insulation is its primary use.

Conventional foams can vary in terms of their physical properties and performance. While they are similar in function, certain situations require specific types of conventional foam, as there are slight differences between them.

It’s the cheapest and often most cost-effective type of foam, often costing a lot less than high resilience foam.

The versatility of conventional foam allows it to be molded and adjusted to suit certain needs. Its shape, density, thickness, and color can all be changed to suit whatever purpose may be required. The typical density of a conventional foam, however, is around 1 LB to 3 LB per cubic foot.

Advantages Of

High Resilience Foam

High resilience foam, as its name suggests, has some definite advantages over conventional foam when it comes to durability. After all, it’s an improvement on ordinary foam, so it’s got to have at least some worthwhile aspects to it.

Many high-quality furniture manufacturers are turning to HR foam to improve their products.

Making a name for yourself as a bespoke furniture creator isn’t easy, and it requires a considerable effort to keep up with advancing technology.

Since new materials are being synthesized every year, the most recent ones are sure to attract top companies for their beneficial properties.

High resilience foam is a relatively recent invention, and is particularly new in the furniture world. Even though it’s a little pricier than conventional foam, manufacturers still buy HR foam in bulk because of its advantageous properties.

Below, you’ll find a list of the various benefits of high resilience foam.

Advantages Of

Conventional Foam

Conventional foam isn’t the most high-tech or best quality material on the market, but it does have its advantages. Many top-of-the-range manufacturers would choose more advanced foam types, but that doesn’t mean that conventional foam isn’t still widely used. Quite the opposite, in fact.

While high resilience foam offers many benefits, there are still instances where you might choose conventional foam over HR foam. It all depends on your budget, your requirements, and what specific purpose you want the foam to serve.

Here are some reasons why you might pick conventional foam over high resilience foam:

Disadvantages Of

High Resilience Foam

Like everything in this world, high resilience foam has its downsides as well as its advantages. Obviously, scientists haven’t quite perfected foam as a material, so each type comes up short in some form or another. Compared to conventional foam, high resilience foam has about an equal number of disadvantages, just in different areas.

The important thing to consider when reading these cons of high resilience foam is that they may not be relevant to you and your desired use.

Comfort, Functionality, Cost

If you’re looking for a type of foam for a specific use, like insulation for instance, you may not be worried about how comfortable it is. Similarly, if you’re after a foam to use in luxury seating, you may not care too much about a high overall cost.

As such, some of the disadvantages listed below may not even be considered downsides, depending on the foam’s intended purpose. It’s therefore worth getting a clear picture of what you want to use the foam for before comparing disadvantages.

In any case, here are some common downsides to high resilience foam:

Disadvantages Of

Conventional Foam

Just like high resilience foam, conventional foam also has its downsides. There’s a reason why more advanced types of foam were created, after all. While conventional foam is perfectly adequate for some purposes, it falls behind significantly in others. High resilience and high density foams were created to address some of these problems.

As such, many of the disadvantages associated with conventional foam are simply advantages to HR foam.

High resilience foam solves many of the issues created by conventional foam, but there are still some aspects in which standard foam remains superior. That said, there are also many areas in which conventional foam still underperforms.

The following are some of the main disadvantages of conventional foam:

When To Use

High Resilience Foam Vs Conventional Foam

Both high resilience foam and conventional foam have their merits, so how do you know when to use one over the other? Well, it all depends on the material’s application. The decision to choose HR foam over conventional foam will ultimately come down to your specific needs and circumstances.

Higher return on investment (ROI)

Choosing one material over the other, therefore, can be a little difficult. It’s hard to know if picking a more expensive option will pay off and bring you a higher return on investment (ROI), or whether it’s worth balancing your budget and sticking to a cheaper alternative.

To this end, our mini guide below should help you figure out exactly when to pick HR foam over conventional foam and vice versa.

Application

For uses where comfort and support is a priority, such as in furniture, HR foam is the better option. Conventional foam is more suited to packaging, insulation, and soundproofing, thanks to its cushioning and heat-resistant properties.

Durability

Since HR foam is far more durable than conventional foam, it provides the better option for longer-lasting purposes. Conventional foam, meanwhile, is much more suited to short-term applications.

Cost

Your budget plays an important role in determining which type of foam to use.

HR foam is typically more expensive than conventional foam, making it a less popular pick among smaller companies or for uses where supreme comfort isn’t required.

Weight

One of the main advantages of conventional foam is that it’s super lightweight. Aside from cost, it’s the main reason why you might pick standard foam types over HR foam. Where a light mass is a priority, such as packaging, conventional foam is the better choice.

Resilience

When it comes to resilience, there is none better than HR foam. High resilience foam can provide incredible support and can retain its shape brilliantly, making it a much better choice than conventional foam in certain applications.

Environmental impact

Even though neither type of foam is particularly green, conventional foam is generally much less environmentally friendly than HR foam.

Outdated processes and more harmful chemicals are used in the production of conventional foam, making HR foam a slightly eco-friendlier choice.

The Future Of

Foam Materials

Technology is constantly evolving, with new developments and more efficient processes being created year after year. Every decade brings new cultural attitudes and unforeseen global events that affect everything right down to foam technology. The future of foam, as with everything, will always be uncertain, but there are lots of indications as to where it may be headed.

As global attitudes shift to favor more environmentally friendly processes, investment in sustainable technologies will continue.

Foam materials will likely become more ethically sourced and sustainably created, and the same can be said for the manufacturing processes involved. As demand for sustainable materials grows, foam manufacturers will increasingly explore the use of biodegradable and renewable materials in their operations.

Technology has developed to such a point that responsive materials can now be created.

Not only will we see more eco-friendly materials, we’ll also likely experience a rise in “smart” materials. Technology has developed to such a point that responsive materials can now be created. These react to environmental factors around them, such as temperature and pressure, to adapt and respond in an appropriate manner when called upon. The insulation and packaging industries are particularly invested in these “smart” technologies.

Nanotechnology in Foams

But technology doesn’t stop there. Foam connoisseurs may have already heard of nanotechnology, but we’re going to hear a lot more of it as the years elapse.

Manufacturers can alter the composition of materials right down to microscopic levels to create foam materials with unique properties.

For instance, nanotechnology can be employed to produce foams with improved thermal insulation or with enhanced shock absorption dynamics. This can help solve a variety of real-world problems and can vastly improve the quality of foam products.

Advancing Foam Recycling

And speaking of problems, we’ll likely see an improvement in the recycling issue which grips the foam industry. Foam recycling technologies are improving and companies are increasingly looking for ways to incorporate recycled materials into new foam products. With any luck, the foam materials of the future will be made of more recycled materials than those at present.

Foam materials can be tailored to meet highly specific requirements for highly specialized applications.

Lastly, as manufacturing processes become more advanced, so too does the potential for customization. Foam materials can be tailored to meet highly specific requirements for highly specialized applications. For instance, more breathable foam can be created or different levels of support can be customized. Overall, then, we’ll see a higher degree of customization stemming from a vast improvement in technology.

Final Thoughts

There are many different foam variants in the world, but the two most common groups are high resilience foam and conventional foam. Both have their strengths and both have their weaknesses, so it makes choosing one over the other a difficult decision.

BUDGET

ENVIRONMENTAL IMPACT

RESILIENCE

DURABILITY

Your ultimate choice will depend on a number of factors, including end purpose, budget, environmental impact, resilience, and durability.

Conventional foam is cheaper than HR foam, but it lacks many of the high quality properties that companies look for in their materials.

It’s ideal for smaller companies with a limited budget, or for businesses where foam only plays a small part in their operations. Instances where the foam isn’t going to be directly used by consumers – such as in insulation and packaging – make the best cases for conventional foam.

High resilience foam,

on the other hand, is better for companies who strive to provide luxury and quality for their customers. It costs more, but you’ll likely get a better ROI for your money.

Due to its impressive resilience, durability, and comfort, HR foam is best suited to furniture and applications where end users will be in frequent direct contact with the foam.

What does high resiliency foam mean?

High resiliency foam is a type of foam that is created to offer better comfort and support than traditional foam while retaining its shape for a longer period. It is popularly used in mattresses, furniture cushions, and car seats because of its durability and ability to absorb energy. Foams that have high resilience are often denser than regular foams, which allows them to maintain their resilience over time. As a result, they are usually more expensive than other types of memory foams.

Is high resilience foam really that much better than conventional foam?

High resilience foam is known to be more supportive and durable compared to traditional foam. Its denser material helps absorb energy better, providing consistent support and comfort over time. Additionally, its construction allows it to maintain its shape for a longer period. High resilience foam is an excellent option for items that receive regular use or movement, such as mattresses, furniture cushions, and car seats. Although it is pricier than conventional foam due to its superior quality and construction, the long-term comfort and durability benefits make the extra cost worthwhile.

What is the difference between high-density foam and high resilience?

High-resilience foam is a pricier foam option that is meant to offer better comfort and support than memory foam or high-density foam. High Resilience Foam is more durable and less likely to flatten over time compared to other foams due to its higher density. This results in better support and greater comfort when sitting or lying down on the cushion, compared to high-density foam. Furthermore, unlike memory foam which compresses when pressure is applied, high-resilience foam is more responsive and retains its shape better.

Is Seating made from High Resilience foam good or bad?

HR foam is a kind of polyurethane foam that offers great support and comfort. It also retains its shape and lasts longer compared to other types of foam. The material possesses an open cell structure and excellent elasticity, allowing it to always return to its original shape. Compared to HR foams, High Density (HD) foams have higher density and hence take longer to recover after being compressed. Generally, HR foam provides greater comfort due to its higher levels of resilience, while HD foam is more supportive and durable in the long run. For this reason, many people prefer seating that is made of both types of foam for optimal comfort and support.

What is the difference between memory foam and High Resilience foam?

The key distinction between memory foam and high-resilience foam lies in their level of responsiveness. Memory foam is slower to regain its original shape after pressure is applied, whereas high-resilience foam bounces back more quickly. High-resilience foam is a better option than memory foam as it provides better support due to its higher density and elasticity. Also, it is more long-lasting as it can better maintain its shape over time. However, it is more expensive compared to regular memory foam due to its superior qualities.

How does high resilience foam hold up to wear and tear?

High resilience foam is a durable and long-lasting material that can resist wear and tear. It is made of denser material that absorbs energy more efficiently and maintains its shape for a longer time. The foam’s open-cell structure evenly distributes weight, preventing too much pressure in one area. As a result, high resilience foam remains comfortable even after extended use. With proper care and maintenance, high resilience foam can last for years without sagging or losing support.

Where can I find high resilience foam furniture?

If you’re looking for furniture made with high resilience foam, you can either visit furniture and mattress stores or search online retailers like Amazon. It’s also a good idea to check with your local furniture store to see if they have any HR foam options. Before making a purchase, make sure to review the product details and user reviews to ensure the piece of furniture is durable and made with quality HR foam.

Why is high resilience foam more expensive than conventional foam?

High resilience foam comes at a higher cost compared to regular foam due to several reasons. It is denser, which makes it maintain its original shape for a longer time. Its ability to absorb energy more effectively ensures consistent comfort and support. Moreover, its construction permits even weight distribution on the surface, making it more durable and long-lasting. Although it is more expensive, these qualities make it worth the extra expense in terms of comfort and durability benefits in the long run.

What are the benefits of conventional foam?

Compared to high resilience foam, conventional foam is a more affordable option that offers good support and comfort, although not as much as high resilience foam. Also, it does not flatten over time and is less likely to develop body impressions with regular use when compared to other foams. Therefore, for everyday use, conventional foam provides enough cushioning and comfort at a lower cost than high resilience foam.

What are the disadvantages of high resilience foam?

High resilience foam has two main drawbacks. Firstly, it is expensive compared to other types of foam due to its superior qualities. Secondly, it can develop permanent body impressions over time more easily than higher density foams. Additionally, some people may experience slight discomfort while sitting or sleeping on HR foam. This is because it takes some time for the foam to evenly distribute the user’s body weight across the surface.